Quality Control

Process Control

In robotic, aerospace and some general engineering, we hold tighter tolerances using a special process developed at our company to produce highest accuracy and least error.

Tooling

Wax Dimension

Software Control

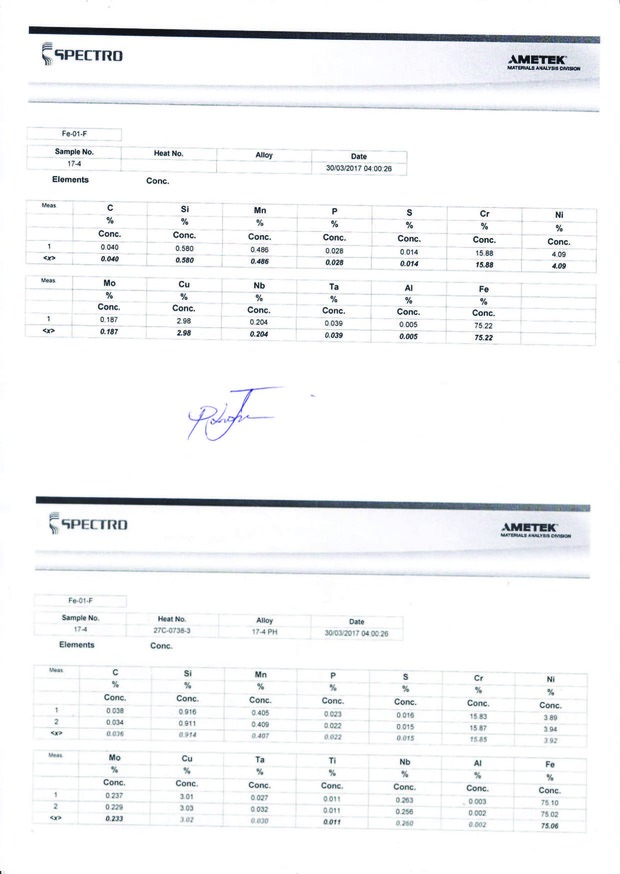

Material Analysis

Traceability Control

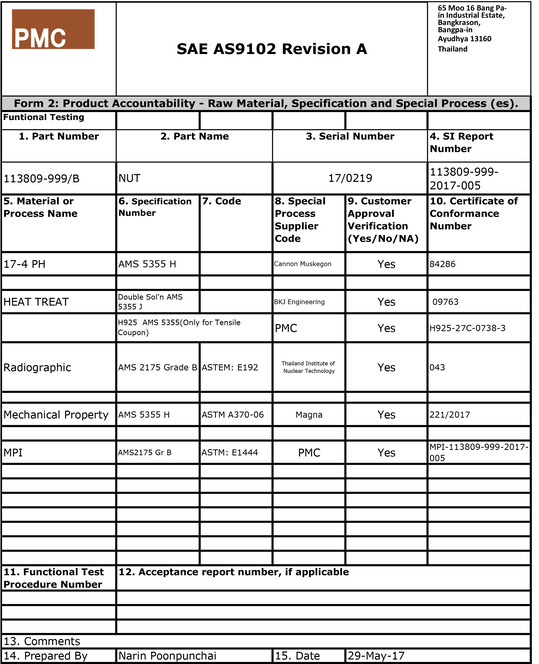

AS9102 Submission Compliance

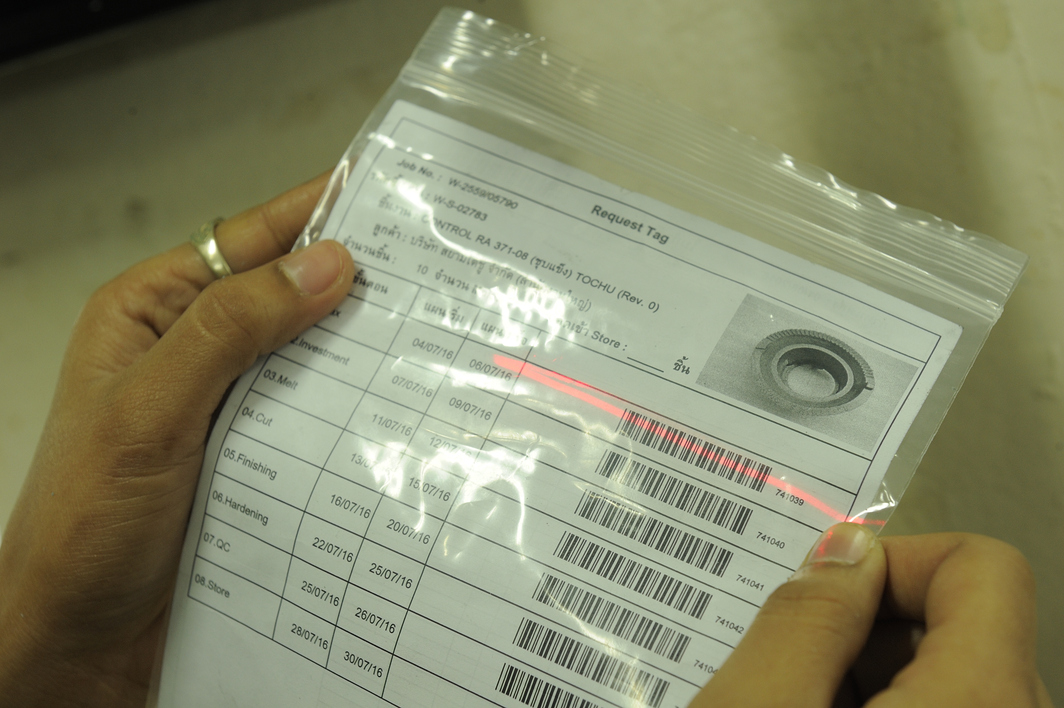

Packaging Barcode

Process Barcode

Job card to Control Process

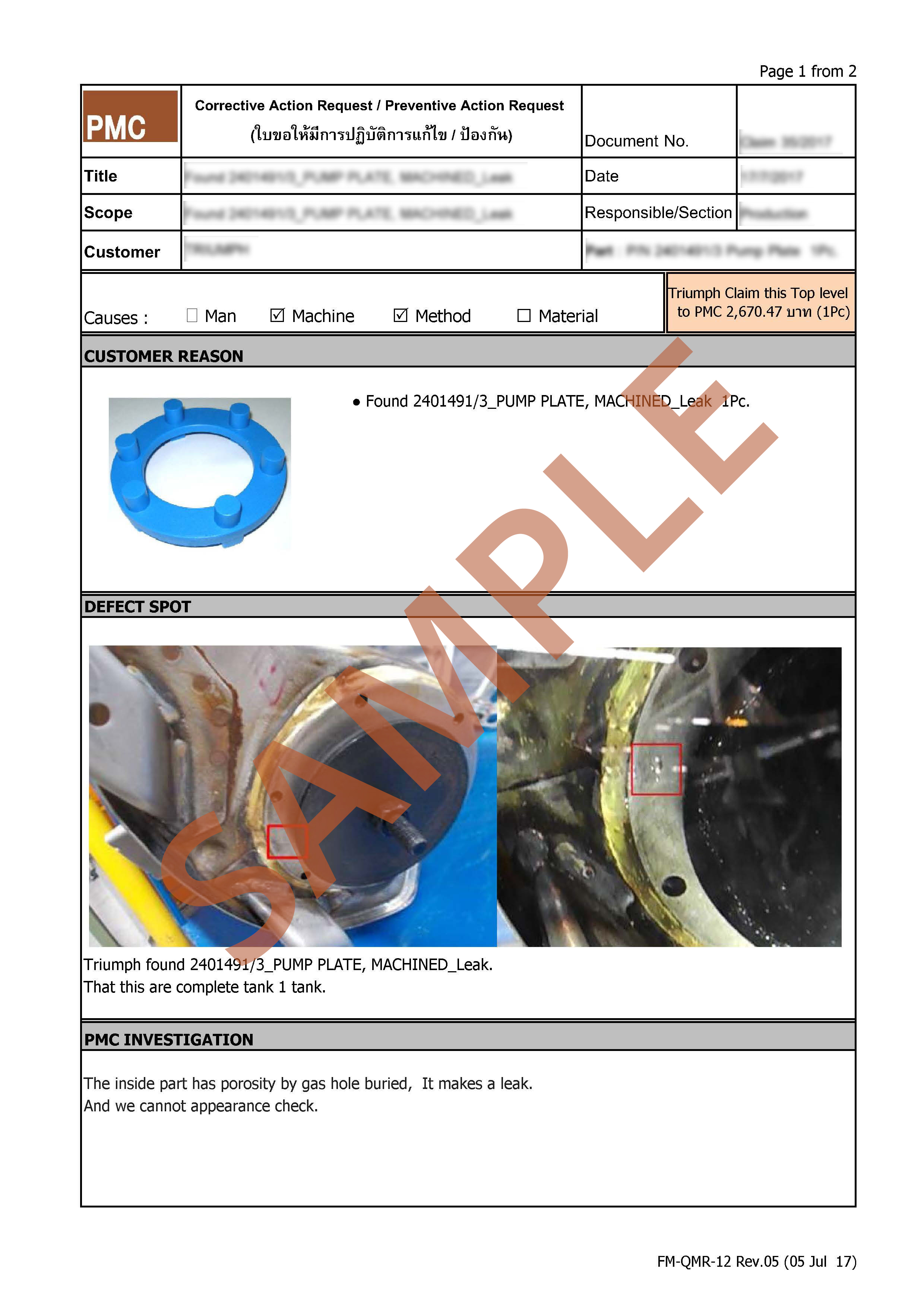

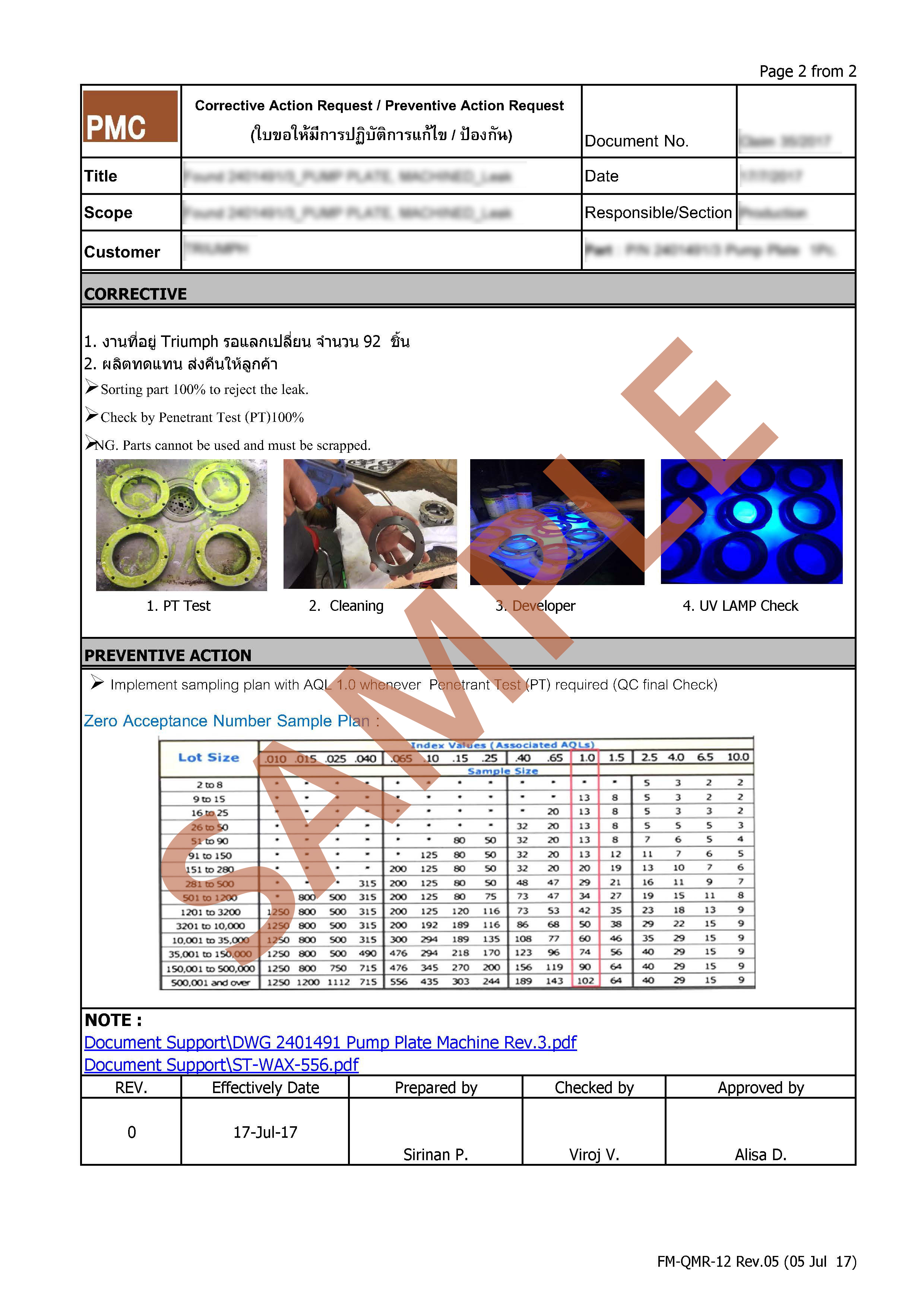

Corrective Action Report