Customer Requirement

At PMC, we value preparation work for optimal production process. The first step in considering investment casting or shell mold process with us is for you to provide product requirements such as conceptual design, 3D/2D plan, rapid prototype or sample products. Once we understand your detailed requirements, our team of experienced engineers will evaluate and recommend the material and will promptly provide quotation with key factors including quantity, price and production timeline for your consideration.

Quality and continuous improvement are our priority. Our team of technical specialists works closely with customers to address common issues of investment casting products such as porosity, sizing and wear and tear. We are available to provide advice and production recommendation to help save cost and ensure applicability of products and quality improvements in production.

From production process to delivery, our goals are to provide reliability and seamlessness to our customers. With over 30 years of production experience, we provide a realistic and reliable estimates on our production timing. Having delivered products to customers worldwide, we have an extensive and reliable network of delivery options for our customers: by land, by sea and by air.

Our team of specialized engineers and technical sales are available to promptly respond to your requests and to provide you with competitive pricing. Our quotation is based on lowest cost methodology and accurate cost-based pricing. We also provide pricing options and recommendations for negotiations with clients and producers.

Lead Time

| Process | General Lead Time |

|---|---|

| Tooling | 2 to 6 weeks |

| Sample Production | 3 to 6 weeks |

| Completing Repeat Orders | 4 to 12 weeks |

Engineering Development

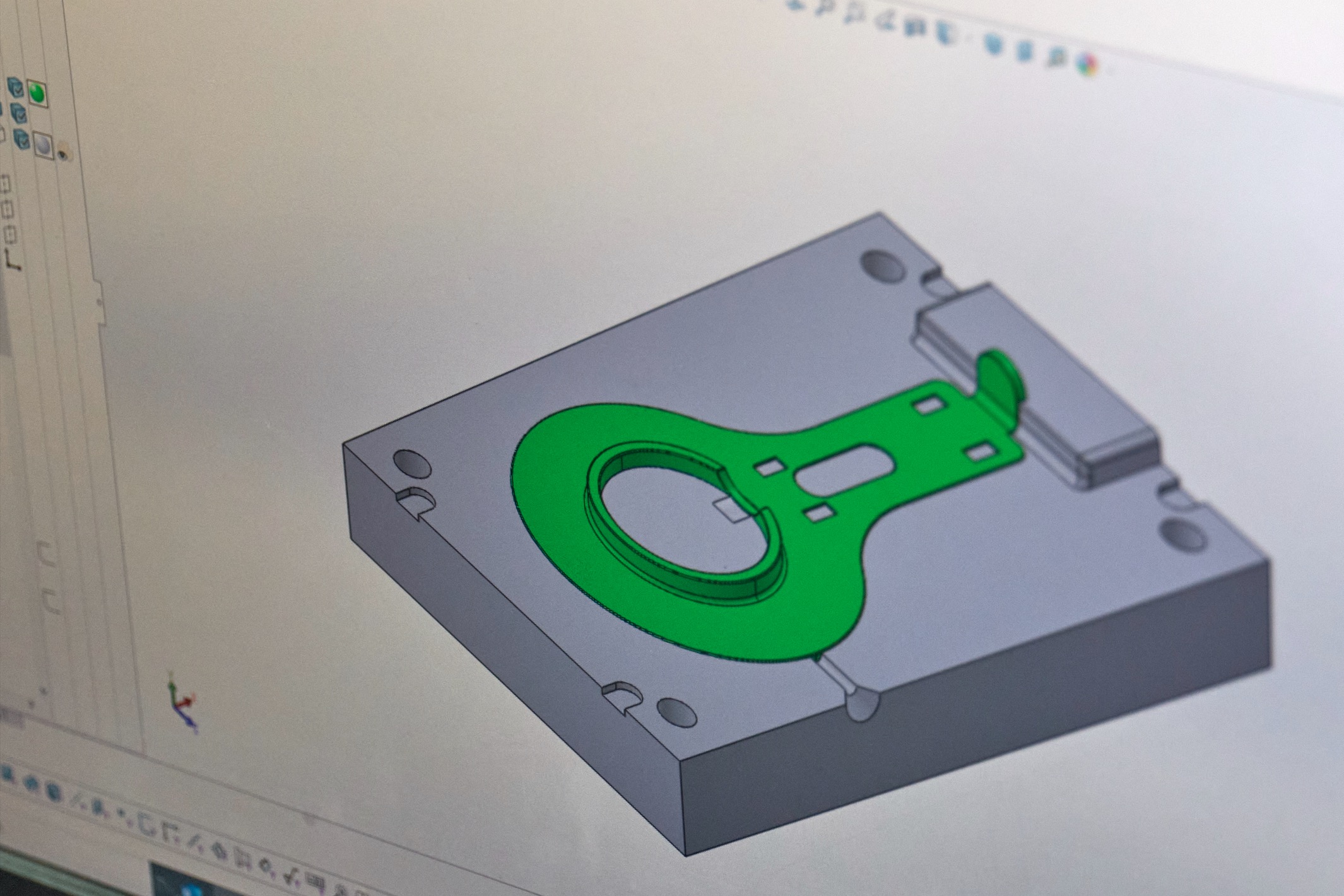

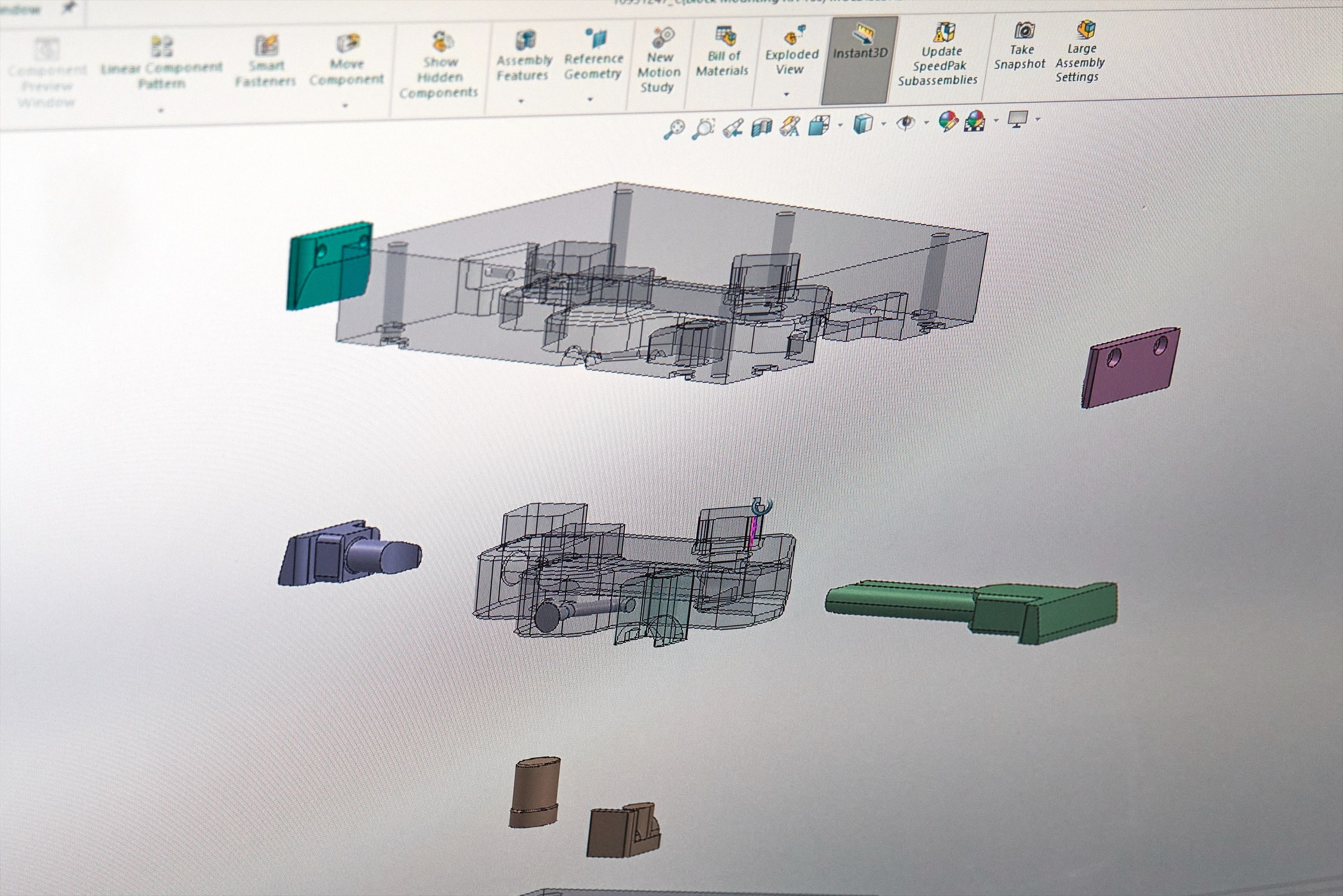

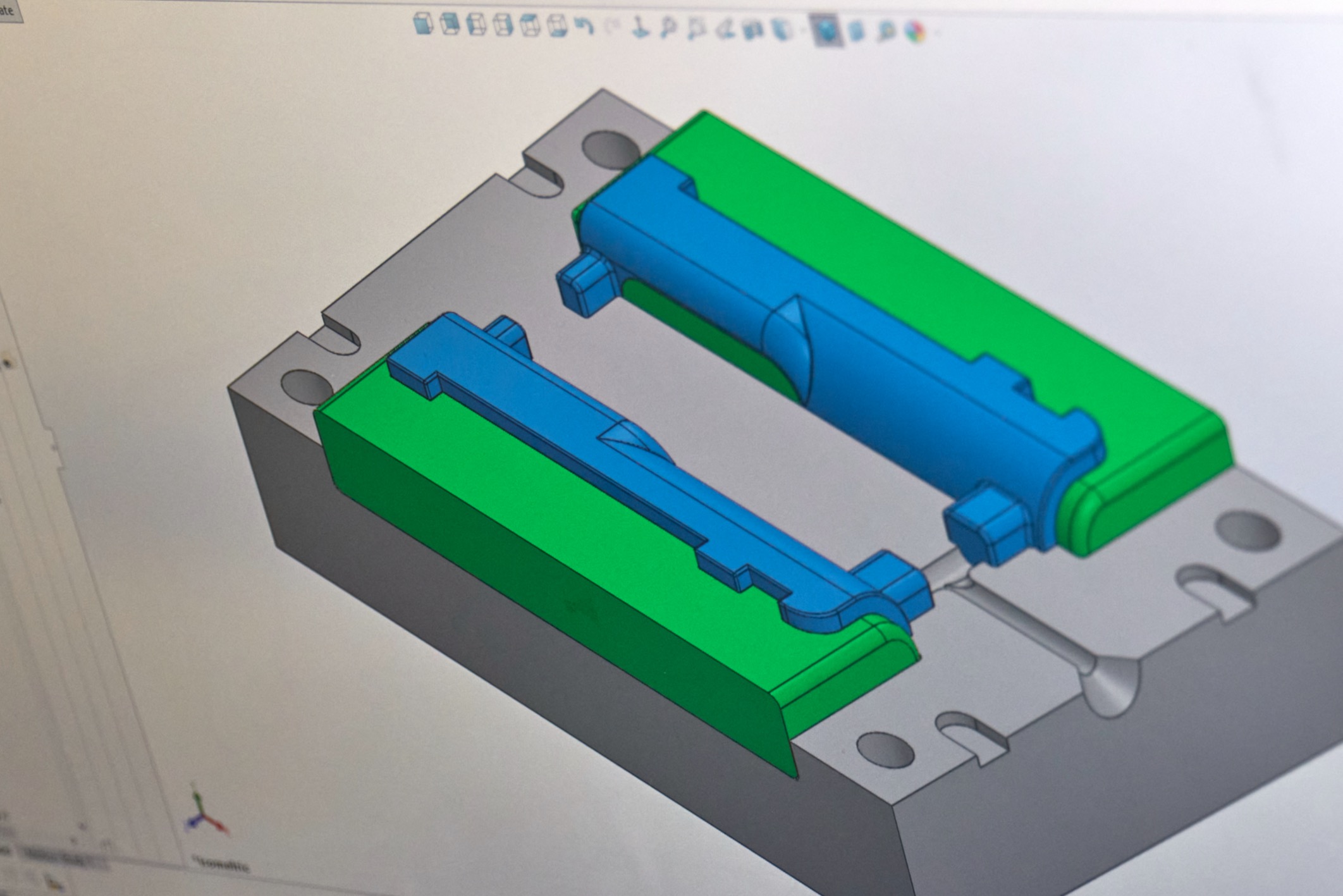

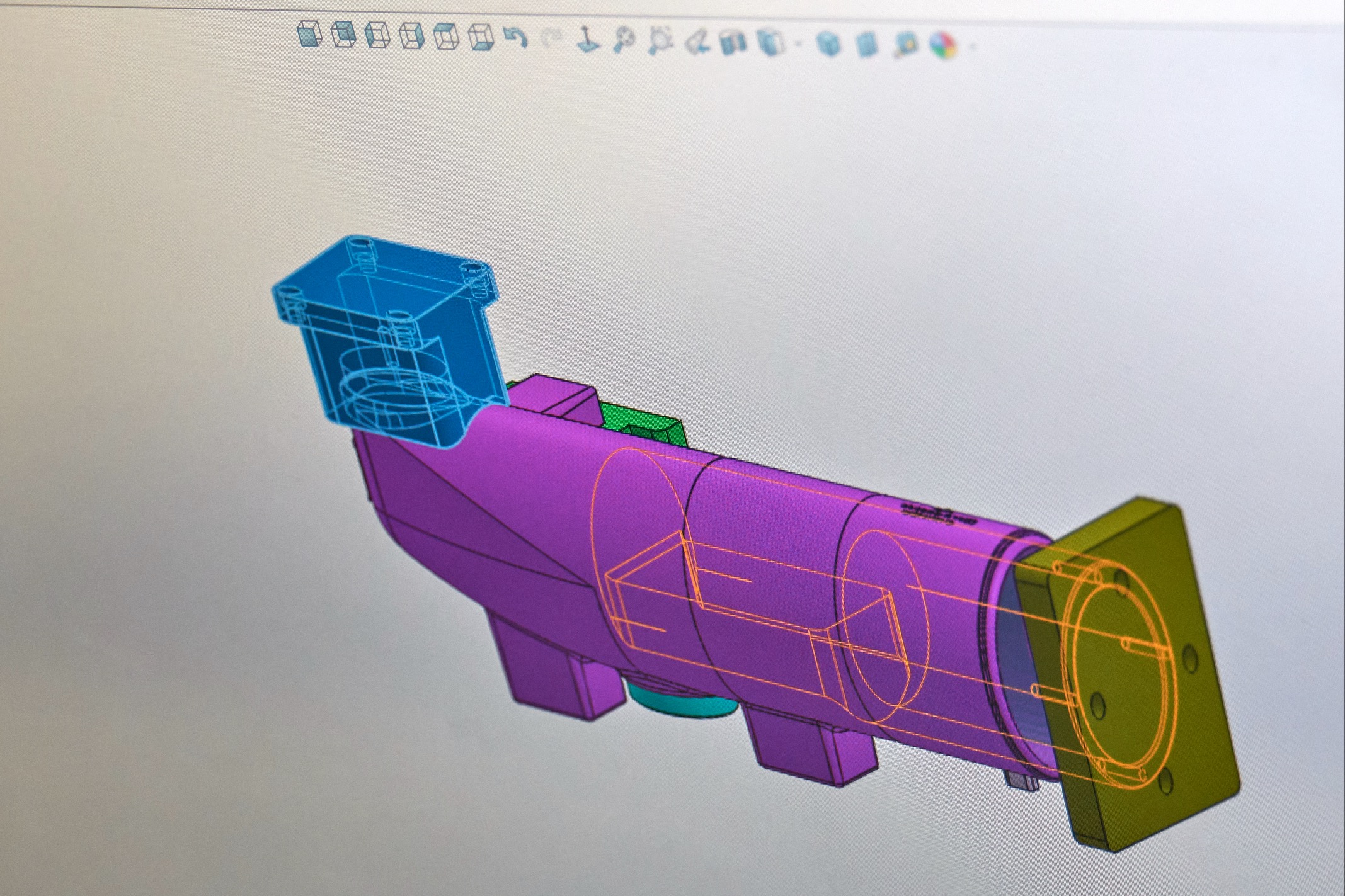

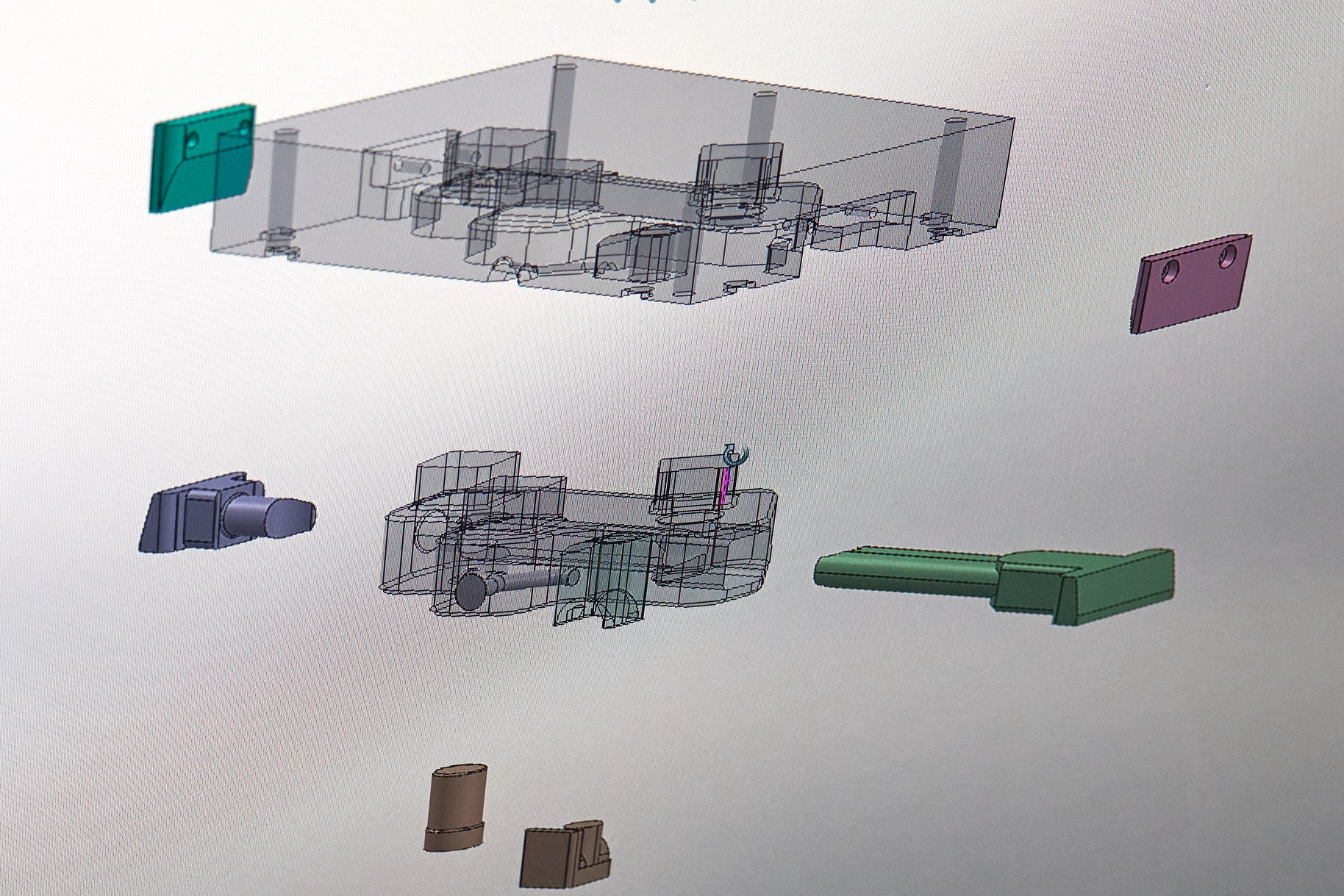

CAD/CAM

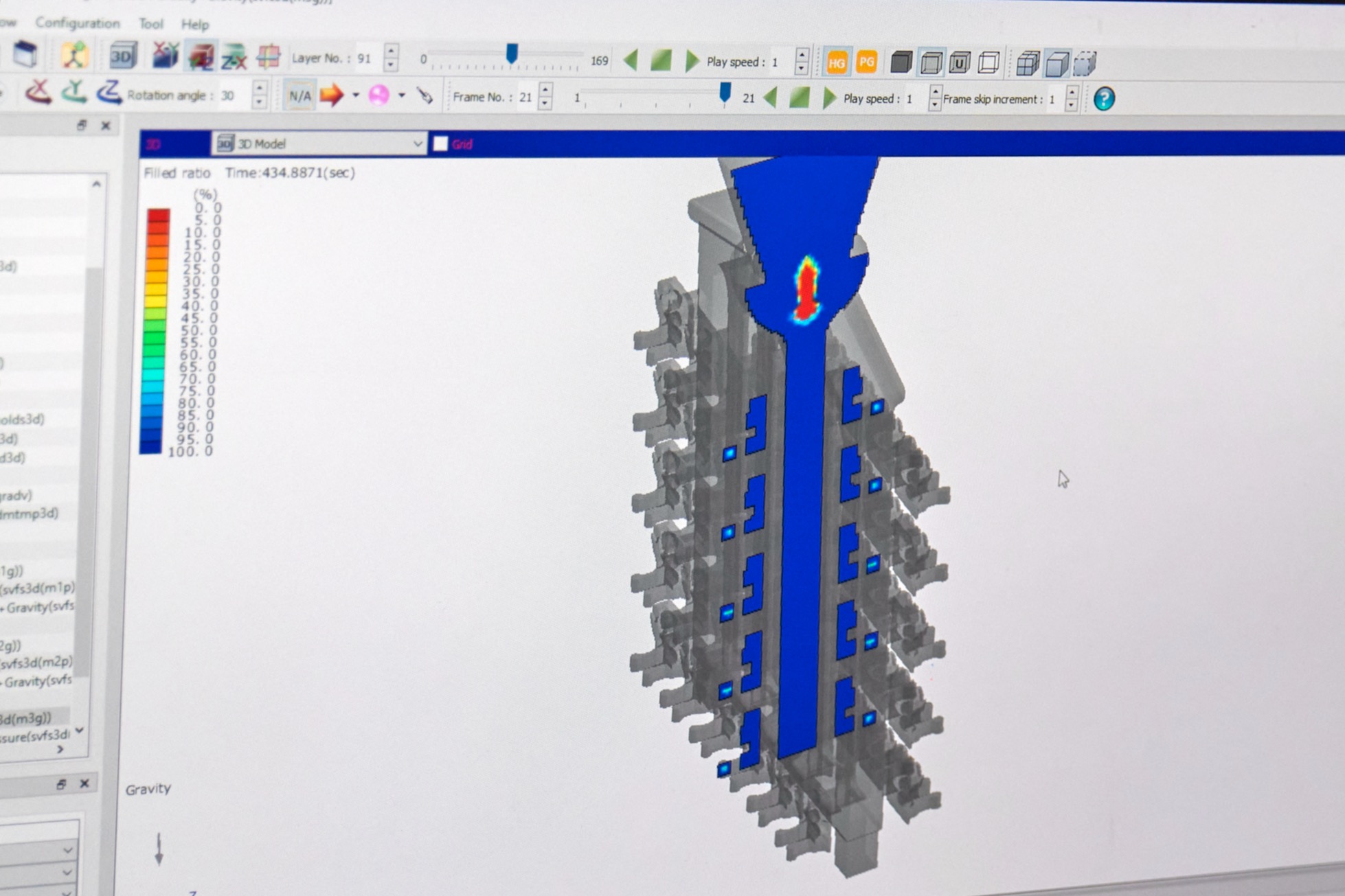

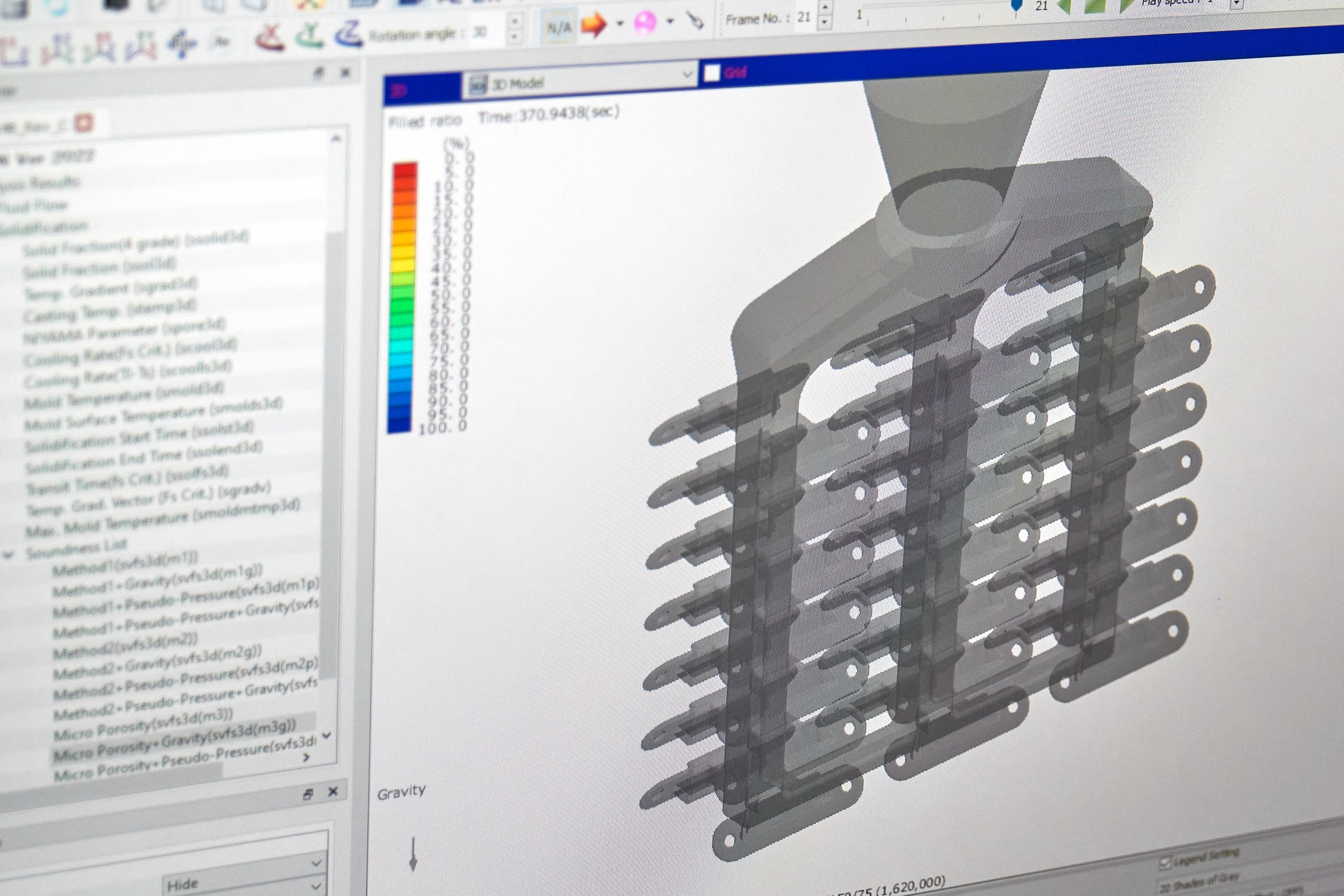

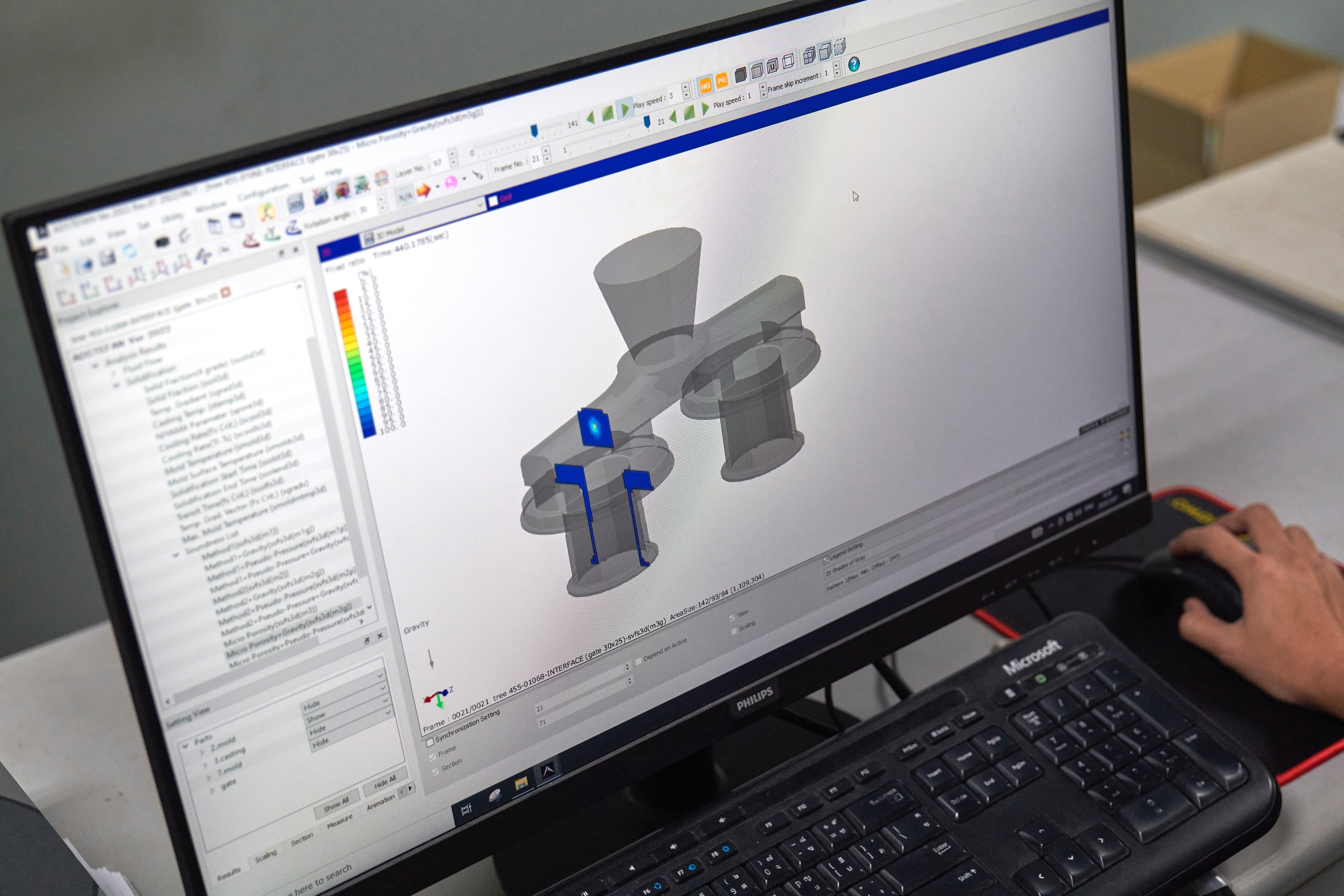

Simulation

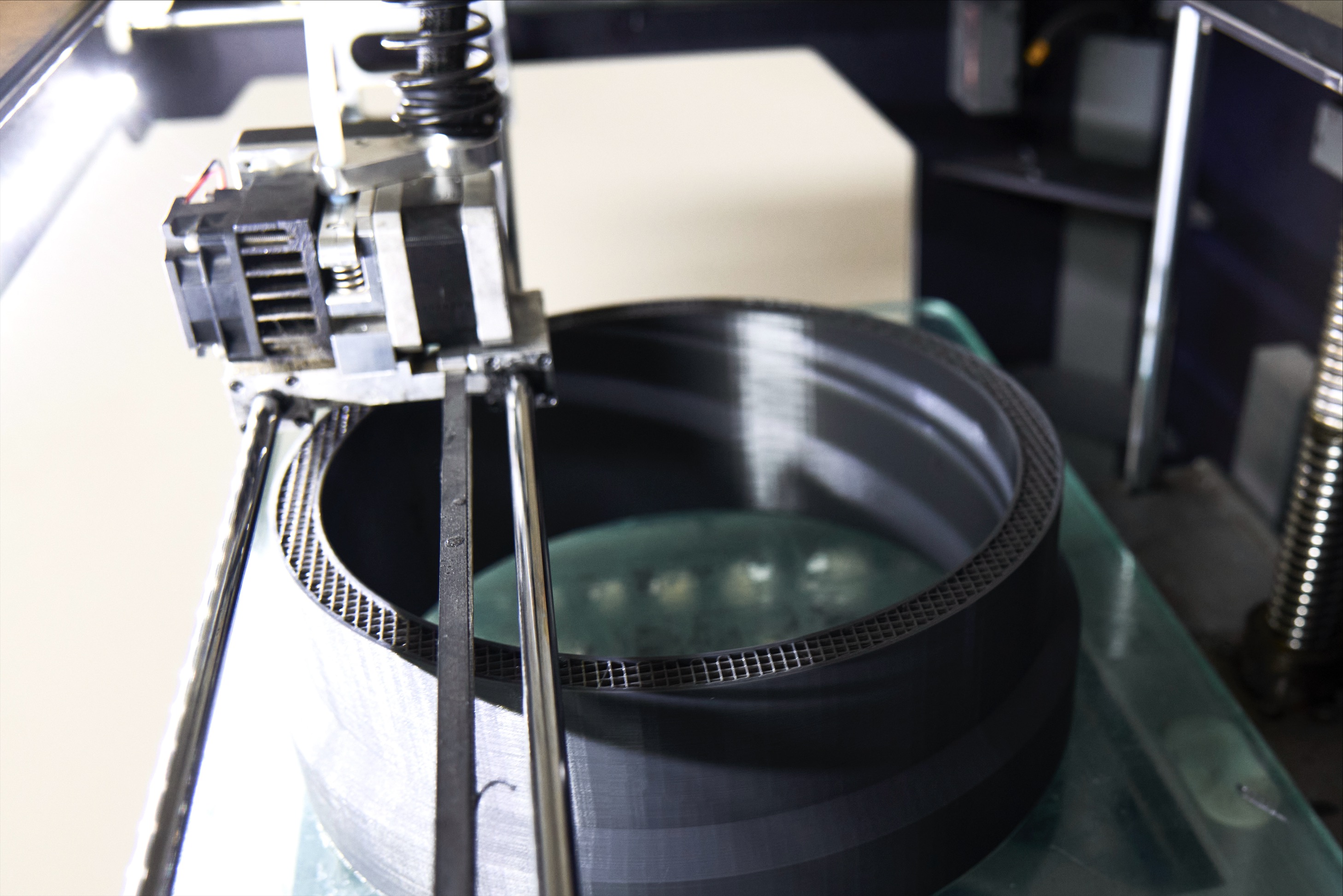

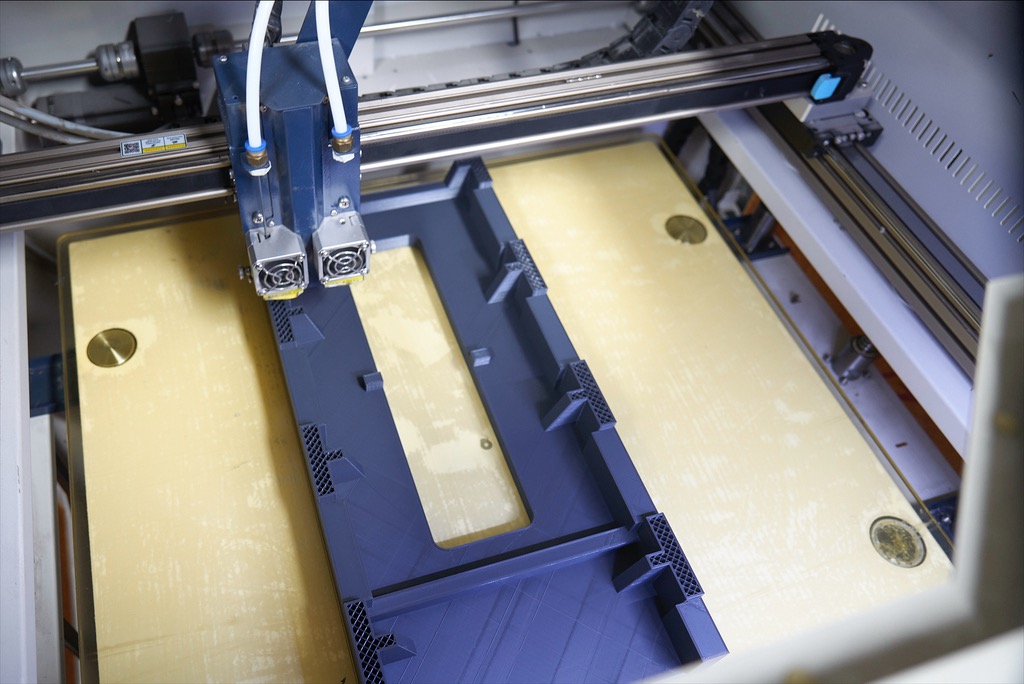

3D Printing

/1 CAD-CAM/1.jpg)

/1 CAD-CAM/2.jpg)

/1 CAD-CAM/3.jpg)

/1 CAD-CAM/4.jpg)

/2 Simulation/1.jpg)