WELCOME TO PMC

PRECISION MANUFACTURING COMPANY LIMITED

We are experts in producing high quality investment castings and shell mold with post processes such as heat treatment, machining, surface finishing and assembly. The products range from very small parts to large and heavy parts, covered for most of industries from ground to sky.

PMC takes pride in the synchronized lean manufacturing process, allowing us to compete in the global market place.

Industries

Services

Investment Casting

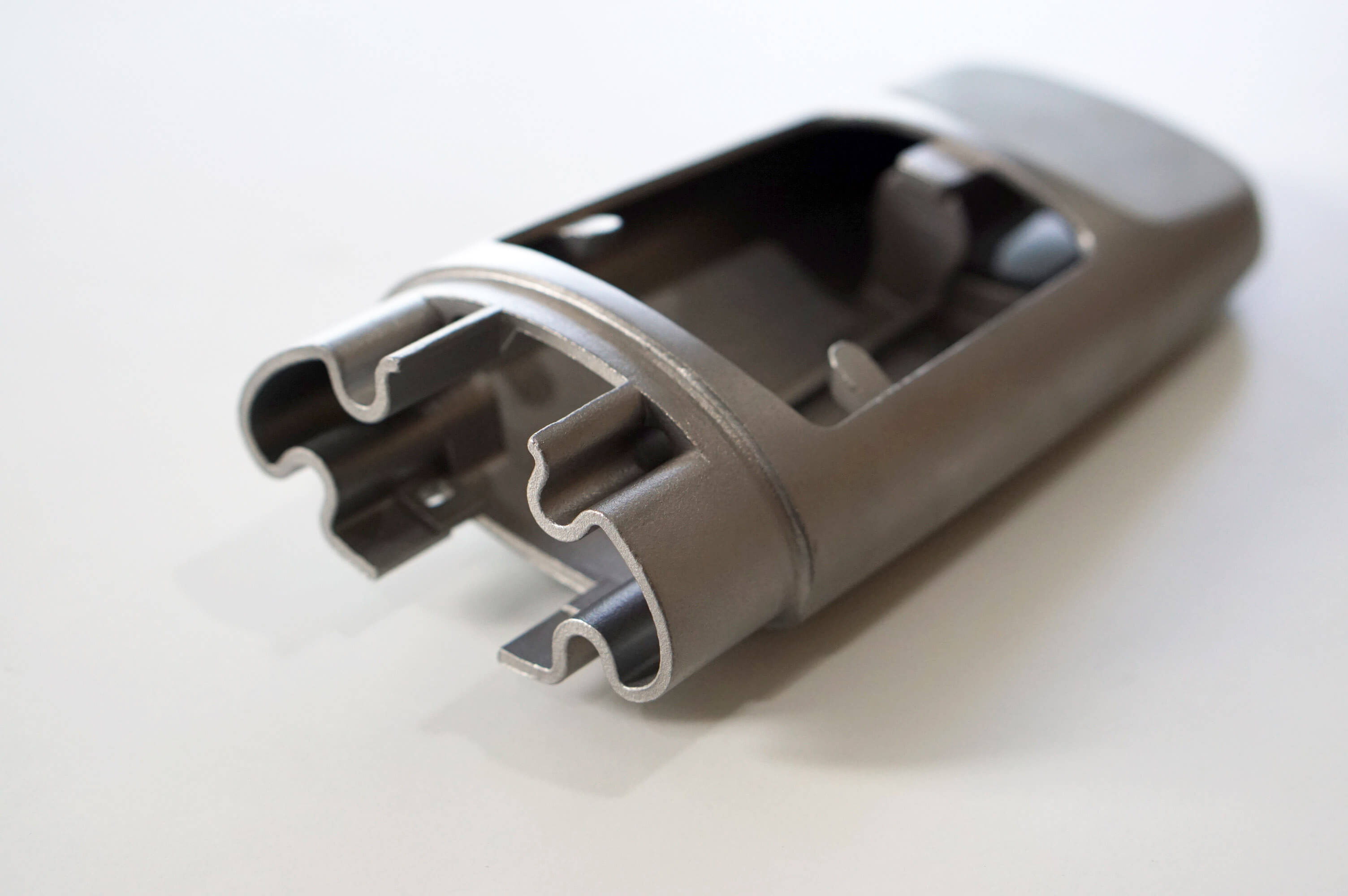

Elevate Your Manufacturing with Investment Casting at PMC

At PMC, we excel in investment casting an advanced method that delivers unmatched precision and quality for a variety of industries, including automotive, aerospace , and oil & gas. Our process allows for intricate designs and high tolerances, significantly reducing the need for extensive machining and minimizing waste.

We offer versatile solutions with a range of materials, from traditional metals like steel and aluminum to modern alloys. This not only ensures durability but also keeps production costs low. With a dedicated team of experienced engineers, we work closely with our clients to tailor our services to their specific needs.

Invest in the future of manufacturing with PMC's innovative investment casting solutions. Our state-of-the-art facilities bring your designs to life with remarkable speed and accuracy.

Contact PMC today to learn how we can transform your ideas into precision-crafted components that meet the highest standards of quality.

Shell Mold

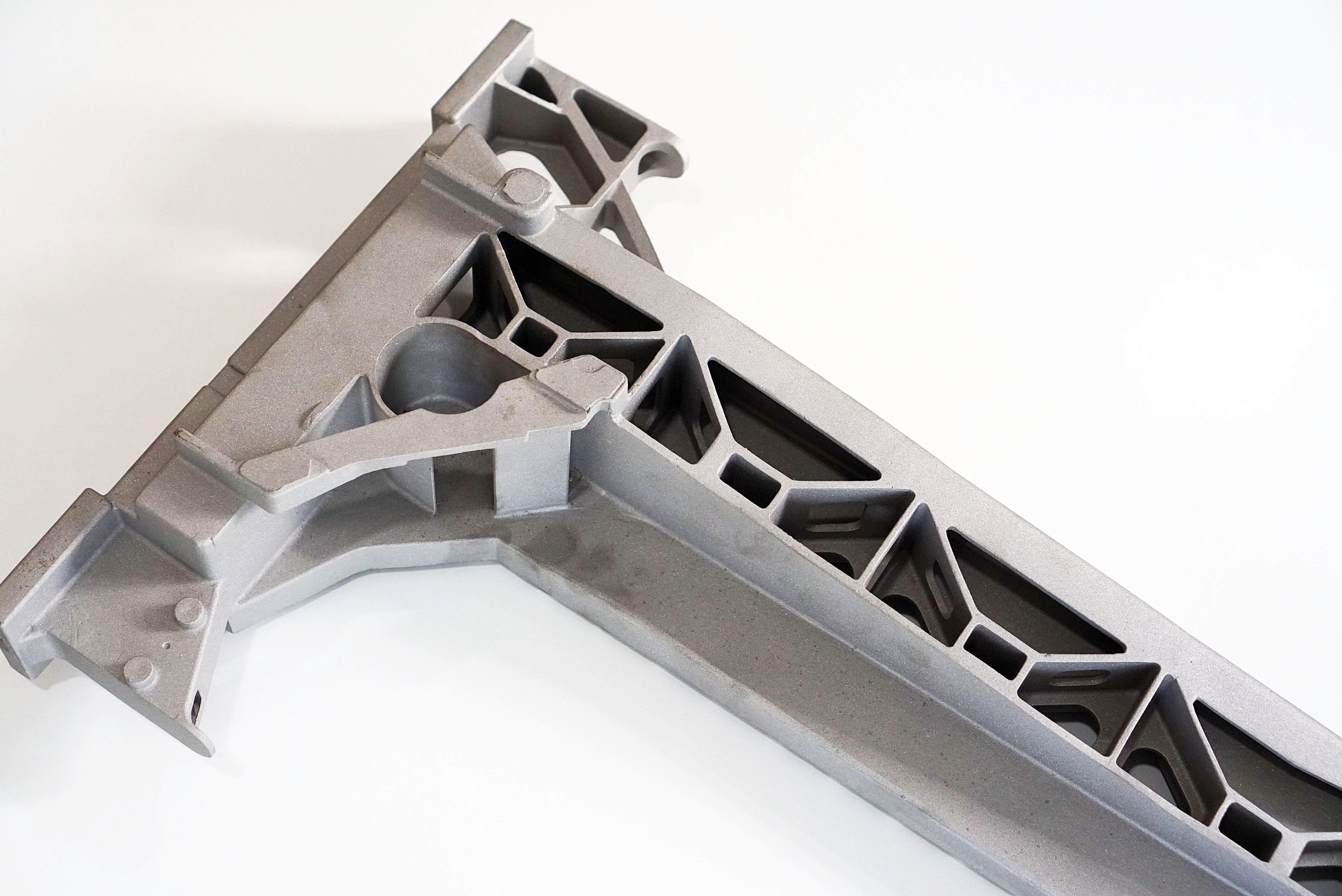

Experience the Future of Manufacturing with Shell Mold Casting at PMC

Step into a new realm of precision with shell mold casting at PMC. This innovative process is your go-to solution for high-quality metal components that demand both accuracy and efficiency. Perfect for a range of industries, including automotive and aerospace, shell mold casting allows for intricate designs and excellent surface finishes that reduce the necessity for secondary machining.

Utilizing a refined technique that combines sand and resin to form molds, we achieve rapid production cycles without sacrificing quality. Our expert team at PMC is dedicated to customizing solutions that fit your unique specifications and material requirements.

When you partner with PMC, you gain access to a swift, cost-effective manufacturing process that enhances your competitiveness in the market.

Let’s connect today and discover how shell mold casting can transform your production capabilities for superior results!

Machining

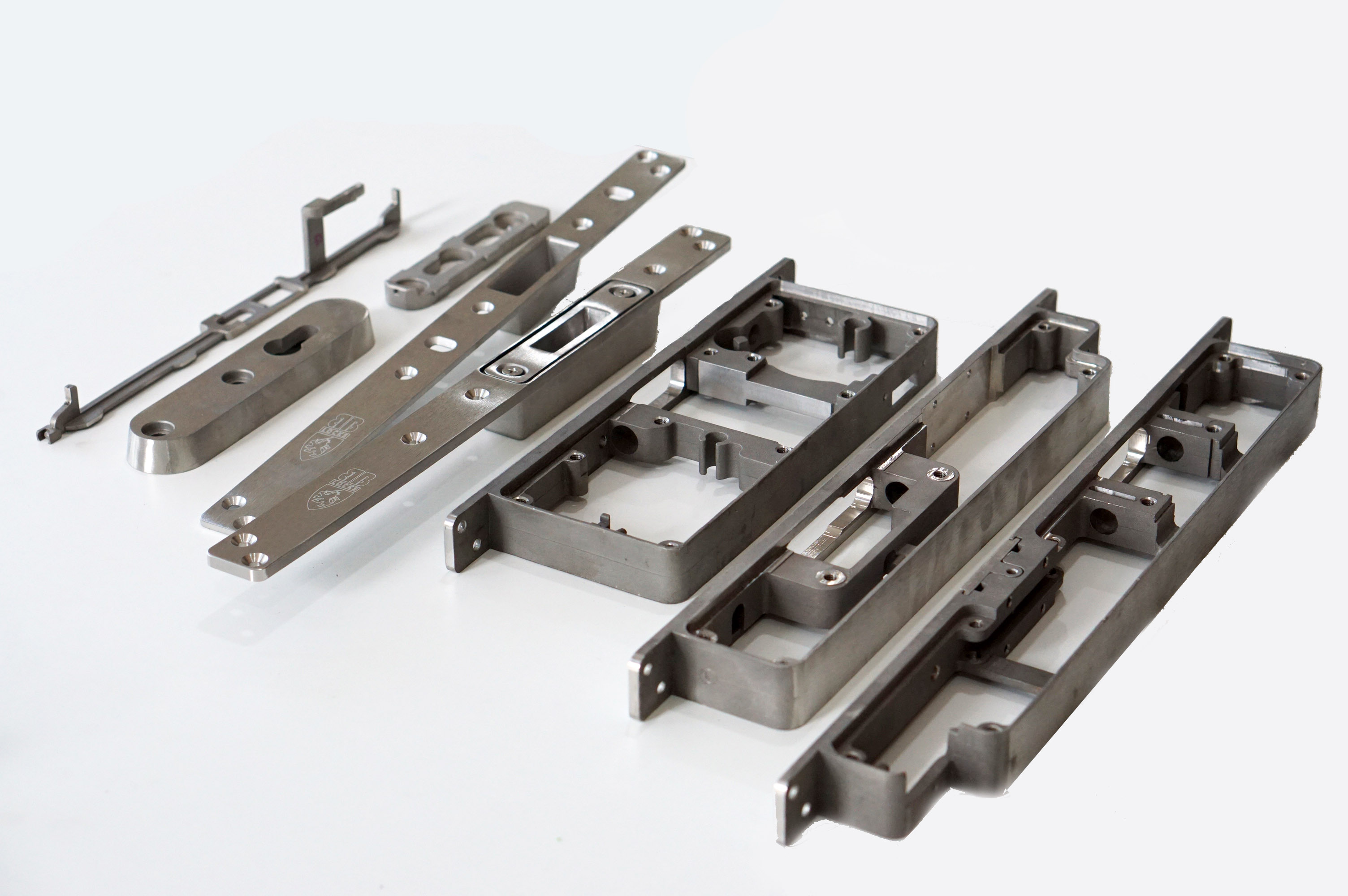

Enhance Your Investment Casting with Precision Machining at PMC

At PMC, we recognize that the perfection of investment casting is just the beginning. Our comprehensive machining services are here to elevate your components to new levels of quality and performance.

With cutting-edge technology at our disposal, our machining process fine-tunes your cast parts to meet precise specifications. From intricate milling and turning to flawless finishing, our expert team ensures that every component achieves the exact tolerances and surface conditions you need.

By seamlessly integrating machining with investment casting, we minimize the chances of errors while optimizing efficiency. This means shorter lead times and reduced costs for your projects, whether you are producing prototypes or large-scale production runs.

Discover how PMC can refine your manufacturing process. Contact us today, and let’s transform your investment-cast components into superior products that truly stand out in the marketplace!

Material

Explore Diverse Casting Materials at PMC

At PMC, we pride ourselves on our ability to cast a wide range of materials, catering to the diverse needs of various industries. Our primary focus is on steel casting, offering numerous grades to suit specific application requirements. From carbon steel to alloy and stainless steel, our skilled team ensures that each material is expertly selected and processed to deliver exceptional strength, durability, and performance.

But our capabilities don’t stop at steel. We also specialize in casting non-ferrous metals such as aluminum, providing versatile solutions for custom projects. This extensive material range enables us to support diverse applications in sectors like automotive, aerospace, and industrial machinery.

With a commitment to quality and innovation, PMC is your trusted partner for all your casting needs.

Reach out today to learn more about our casting capabilities and how we can help bring your project to life with the right materials!

Quality Equipment

Precision and Assurance: Quality Control Equipment at PMC

At PMC, we prioritize quality in every aspect of our manufacturing process, and our advanced quality control equipment plays a vital role in achieving this goal. Equipped with cutting-edge inspection tools and technologies, we ensure that every component meets the highest industry standards.

Our quality control process includes sophisticated machinery such as coordinate measuring machines (CMM) and non-destructive testing equipment, which allow us to accurately assess dimensions, tolerances, and material integrity. Regular calibration and maintenance of our equipment guarantee consistent performance and reliability.

We also employ advanced software solutions that facilitate data analysis and tracking, enabling us to identify trends and areas for improvement proactively. Our dedicated quality assurance team conducts rigorous inspections at various production stages, ensuring that any potential issues are quickly addressed.

By investing in top-tier quality control equipment, PMC reaffirms its commitment to providing superior products that exceed customer expectations every time.

Product Development

Engineering-Focused Product Development at PMC

At PMC, we specialize in product development that demands engineering expertise and innovation. Our process begins with a deep collaboration with you to fully understand your vision and goals. Our skilled engineers utilize advanced tools like computer-aided design (CAD) software to create precise models of your product, allowing for iterative refinements and detailed visualization.

Material selection is pivotal in our development process. We leverage our vast knowledge of various metals, including different grades of steel and non-ferrous materials, to ensure optimal performance and durability. Rigorous testing protocols follow, validating the design under real-world conditions before moving to production.

Our commitment to excellence doesn’t stop at design. We provide continuous support throughout the lifecycle of your product, making improvements as needed based on performance feedback.

Choose PMC for your engineering-driven product development needs where innovative ideas are transformed into high-quality, reliable solutions!